Understanding the Basics of Duct Design

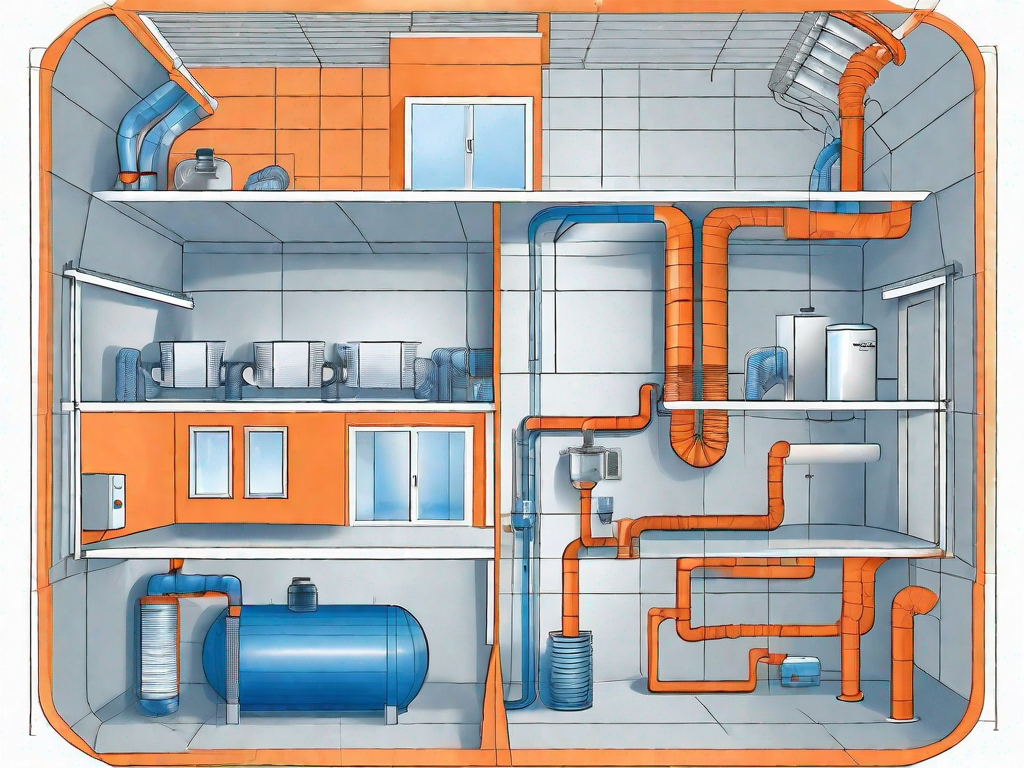

Duct design plays a crucial role in the performance of heating, ventilation, and air conditioning (HVAC) systems. It determines the efficiency of airflow, the distribution of conditioned air, and the overall comfort of a space. When it comes to duct design, there are several key aspects to consider, from energy efficiency and indoor air quality to the choice of materials and insulation. Let's delve into the fundamentals of duct design and explore the factors that need to be taken into account for optimum system performance.

The Importance of Proper Duct Design

Proper duct design is essential for achieving energy efficiency and cost savings. When ducts are inefficient or inadequately designed, it can lead to airflow restrictions, increased energy consumption, and higher utility bills. On the other hand, well-designed ductwork ensures consistent air distribution, minimizes air leaks, and allows the HVAC system to operate at peak performance.

When it comes to duct design, there are several key factors to consider. One important aspect is the size of the ducts. If the ducts are too small, it can create resistance to airflow, causing the HVAC system to work harder and consume more energy. Conversely, if the ducts are too large, it can lead to inefficient airflow and wasted energy. Properly sized ducts are crucial for maintaining optimal airflow and energy efficiency.

Another factor to consider in duct design is the layout and configuration of the ductwork. The path that the air takes through the ducts can greatly impact its efficiency. A well-designed layout ensures that the air flows smoothly and evenly throughout the space, avoiding any obstructions or restrictions. This not only improves energy efficiency but also helps to maintain a comfortable indoor environment.

Energy Efficiency and Cost Savings

An important aspect of duct design is ensuring that the system operates with minimal energy loss. Efficient ductwork helps to reduce the workload on the HVAC system, resulting in lower energy consumption and cost savings over time. By optimizing the airflow and minimizing air leaks, duct design can greatly contribute to improved energy efficiency and reduced environmental impact.

In addition to proper sizing and layout, insulation is another crucial element in duct design. Insulating the ductwork helps to prevent heat gain or loss, ensuring that the conditioned air remains at the desired temperature as it travels through the ducts. This reduces the need for the HVAC system to compensate for temperature fluctuations, leading to energy savings and improved comfort.

Furthermore, duct design also takes into account the location of the ducts. Placing the ductwork in conditioned or insulated spaces, such as within the building envelope, can help to minimize heat transfer and energy loss. This strategic placement of the ducts contributes to overall energy efficiency and cost savings.

Indoor Air Quality and Comfort

In addition to energy efficiency, proper duct design also plays a significant role in maintaining good indoor air quality and comfort. When the ductwork is designed correctly, it helps to evenly distribute conditioned air throughout the space, avoiding hot or cold spots. This ensures a consistent and comfortable temperature throughout the building.

Moreover, proper duct design helps to minimize the risk of pollutants, allergens, and contaminants being circulated in the indoor air. By ensuring that the ducts are sealed properly and free from leaks, it prevents the infiltration of dust, mold, and other harmful particles. This promotes healthier indoor air quality and reduces the risk of respiratory issues or allergies.

In conclusion, proper duct design is crucial for achieving energy efficiency, cost savings, and maintaining good indoor air quality and comfort. By considering factors such as duct size, layout, insulation, and location, it is possible to optimize the performance of the HVAC system and create a healthier and more comfortable living or working environment.

Fundamental Principles of Duct Design

To achieve optimal duct performance, it is crucial to understand the fundamental principles of duct design. This involves considering airflow basics, duct size, layout, and other important factors.

When it comes to duct design, airflow basics play a significant role. Proper airflow is essential for achieving efficient heating and cooling. It is important to take into account factors such as the required air volume, distribution, and pressure. By ensuring adequate airflow throughout the system, ductwork can deliver the right amount of conditioned air to each room or area, ensuring comfort and energy efficiency.

In addition to airflow basics, duct size and layout are critical considerations in duct design. Improper sizing can result in inadequate airflow, causing system inefficiencies and reduced comfort. It is essential to carefully calculate the appropriate duct size based on the specific requirements of the HVAC system and the space it serves. This ensures that the system can deliver the necessary airflow without any restrictions or imbalances.

Furthermore, the layout of ducts is equally important. Poorly planned duct layout can lead to pressure imbalances, noise issues, and airflow restrictions. It is crucial to design the duct system in a way that minimizes resistance and maximizes efficiency. This involves considering factors such as the location of supply and return vents, the path of the ducts, and any obstacles that may impede airflow.

Another aspect to consider in duct design is the material used for the ductwork. Different materials have varying properties that can affect airflow and energy efficiency. Common materials used for ductwork include sheet metal, fiberglass, and flexible ducts. Each material has its advantages and disadvantages, and the choice should be based on factors such as cost, durability, and ease of installation.

Proper insulation is also crucial in duct design. Insulating the ductwork helps prevent energy loss and ensures that the conditioned air remains at the desired temperature as it travels through the system. Insulation materials such as fiberglass or foam board can be used to reduce heat gain or loss, depending on the climate and the location of the ducts.

In conclusion, understanding the fundamental principles of duct design is essential for achieving optimal HVAC system performance. By considering factors such as airflow basics, duct size, layout, material selection, and insulation, ductwork can be designed to deliver efficient and comfortable heating and cooling throughout a space.

Materials Used in Ductwork

When it comes to ductwork, different materials can be used. The two most common options are metal ducts and flexible ducts, each with their own advantages and considerations.

Metal Ducts

Metal ducts, such as galvanized steel or aluminum, are durable and offer excellent fire resistance. They are typically used in commercial or industrial settings where the duct system is subject to higher pressure and temperature demands. Metal ducts are often fabricated on-site to fit specific requirements, and careful sealing is necessary to prevent air leakage.

Galvanized steel ducts are made by coating steel sheets with a layer of zinc, providing corrosion resistance and durability. These ducts are commonly used in HVAC systems due to their strength and ability to handle high-pressure airflow. Aluminum ducts, on the other hand, are lightweight and easy to install, making them a popular choice for residential applications.

In commercial settings, metal ducts are often insulated to prevent heat loss or gain and reduce noise transmission. Insulation materials such as fiberglass or foam are wrapped around the ducts, improving energy efficiency and maintaining a comfortable indoor environment.

Flexible Ducts

Flexible ducts are a more versatile option, often used in residential applications. They are made of a combination of plastic and metal wire, allowing for easy installation and flexibility in routing. The plastic inner core provides smooth airflow, while the metal wire helix provides structural support.

One of the main advantages of flexible ducts is their ability to navigate around obstacles, making them ideal for retrofitting or situations where rigid metal ducts cannot be easily installed. They are commonly used in residential HVAC systems to distribute conditioned air to different rooms.

When installing flexible ducts, it is essential to avoid sharp turns or kinks that can restrict airflow. These restrictions can lead to reduced system performance and increased energy consumption. Proper insulation and sealing are also necessary to prevent air leaks and maintain energy efficiency.

Flexible ducts come in various sizes and lengths, allowing for customization based on the specific requirements of the HVAC system. They are often pre-insulated with a layer of fiberglass or foam to enhance thermal efficiency and reduce noise transmission.

In conclusion, the choice between metal ducts and flexible ducts depends on the specific needs of the application. Metal ducts offer durability and fire resistance, making them suitable for commercial or industrial settings. On the other hand, flexible ducts provide versatility and ease of installation, making them a popular choice for residential HVAC systems. Proper installation, insulation, and sealing are crucial for both types of ducts to ensure optimal performance and energy efficiency.

The Role of Insulation in Duct Design

Insulation is a critical component in duct design, providing thermal protection and preventing energy loss.

Reducing Heat Loss

Insulating ductwork helps to minimize heat loss during the distribution of conditioned air. By insulating the ducts, the temperature of the air inside is maintained, reducing the potential for heat exchange with the surrounding environment. This not only improves energy efficiency but also ensures that the heated or cooled air reaches its intended destination without unnecessary loss.

Preventing Condensation

Another key benefit of insulation in duct design is the prevention of condensation. When warm air passes through cooler ducts, it can cause condensation to form, leading to moisture-related issues such as mold growth or material degradation. Proper insulation helps to maintain consistent temperatures and prevent condensation formation, safeguarding both the ductwork and indoor air quality.

Common Duct Design Mistakes to Avoid

While understanding the basics of duct design is crucial, it is equally important to be aware of common mistakes that should be avoided.

Incorrect Sizing

One of the most significant errors in duct design is improper sizing. Undersized ducts can result in restricted airflow, inadequate temperature control, and increased energy consumption. Oversized ducts, on the other hand, can lead to reduced airflow velocity, inefficient heating or cooling, and excessive noise. Careful calculations and consideration of system requirements are necessary to ensure proper duct sizing.

Poor Installation Practices

The quality of ductwork installation plays a crucial role in its performance. Improper installation techniques, such as poorly sealed joints or gaps, can lead to air leaks, compromising system efficiency and indoor air quality. It is essential to follow industry best practices and work with qualified professionals to ensure proper installation and minimize potential issues.

By understanding the basics of duct design, considering factors such as energy efficiency, airflow, materials, insulation, and avoiding common mistakes, a well-designed duct system can contribute to optimal HVAC system performance, energy savings, and enhanced indoor comfort and air quality.