Understanding Duct External Static Pressure

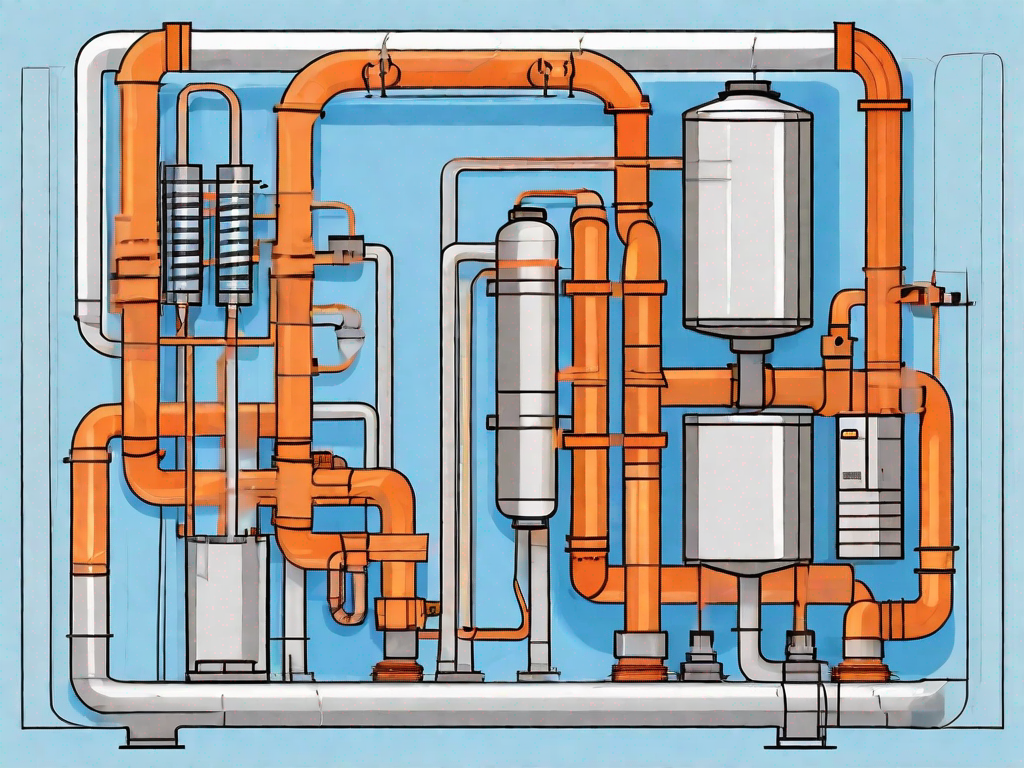

Duct external static pressure is an important concept in HVAC systems. It refers to the resistance that air encounters as it flows through the ductwork. Understanding this pressure is crucial for ensuring proper airflow and efficient system performance. In this article, we will delve into the basics of duct external static pressure, factors influencing it, measuring techniques, and troubleshooting common issues.

The Basics of Duct External Static Pressure

Duct external static pressure, often abbreviated as ESP, is a measure of the resistance that air encounters as it moves through the ductwork system. It is caused by various factors such as friction, changes in duct size and shape, and airflow velocity. ESP is typically measured in units of inches of water column (in. w.c.) or Pascals (Pa).

When air flows through a duct, it experiences resistance due to the friction between the air molecules and the inner surface of the duct. This frictional resistance, known as duct friction, is influenced by the roughness of the duct material and the velocity of the air. Additionally, changes in duct size and shape, such as bends, elbows, and transitions, can further increase the external static pressure.

Another factor that contributes to duct external static pressure is the airflow velocity. As air moves faster through the ductwork, it encounters more resistance, resulting in higher ESP. This is why it is important to properly size and design duct systems to ensure that the airflow velocity remains within acceptable limits.

Importance of Duct External Static Pressure

Understanding and controlling duct external static pressure is crucial for several reasons. First, high ESP can lead to reduced airflow, resulting in inadequate heating or cooling performance. When the external static pressure is too high, the air struggles to flow through the ducts, leading to decreased airflow at the supply registers. This can result in uneven temperature distribution and discomfort for building occupants.

On the other hand, low ESP can cause excessive airflow and place unnecessary strain on the system components. When the external static pressure is too low, the air moves too easily through the ducts, leading to higher airflow rates than intended. This can overload the equipment, causing it to work harder and potentially leading to premature failure.

Proper ESP helps ensure balanced airflow throughout the ductwork and efficient operation of HVAC systems. By maintaining the appropriate external static pressure, the system can deliver the required amount of conditioned air to each room, providing optimal comfort and energy efficiency.

It is important to note that duct external static pressure is not a fixed value. It can vary depending on factors such as the length and diameter of the ducts, the number of bends and fittings, the type of duct material, and the condition of the ductwork. Regular inspection and maintenance of the duct system are essential to identify and address any issues that may affect the external static pressure.

Factors Influencing Duct External Static Pressure

When it comes to the external static pressure (ESP) of ducts, several factors come into play. Understanding these factors is crucial for ensuring the efficient operation of HVAC systems. Let's dive deeper into the key elements that influence ESP.

Duct Size and Shape

The size and shape of the ducts have a significant impact on the external static pressure. Smaller and more restrictive ducts tend to have higher ESP due to increased friction. As air flows through these narrow passages, it encounters more resistance, resulting in higher pressure. On the other hand, larger ducts provide a more open pathway for air to move, reducing friction and lowering ESP.

Furthermore, changes in duct shape, such as bends or transitions, can also affect the overall system performance. These alterations can cause pressure drops, disrupting the smooth flow of air. It is essential to carefully design duct systems, considering the optimal size and minimizing sharp turns or abrupt changes in direction.

Airflow Velocity

The velocity at which air moves through the ductwork is another crucial factor influencing external static pressure. Higher velocities increase pressure losses due to increased friction between the air and the duct walls. This increased friction results in higher ESP. Conversely, lower velocities can lead to inadequate airflow, causing inefficiencies in the system.

It is important to strike the right balance when it comes to airflow velocity. Designing the ductwork to maintain an appropriate velocity ensures that the system operates efficiently without unnecessary pressure losses. This involves considering factors such as the required airflow volume, the size of the ducts, and the available static pressure from the fan.

Duct Material and Installation

The material used for the ductwork and the quality of installation can significantly impact external static pressure. The surface characteristics of the ducts play a role in determining friction losses. Rough surfaces can cause turbulence and increase pressure losses, while smooth surfaces minimize resistance and maintain optimal ESP.

Proper installation is equally important. Improperly sealed ducts can result in air leakage, leading to pressure drops and reduced system efficiency. Additionally, poorly insulated ducts can contribute to heat gain or loss, affecting airflow and pressure. Ensuring that ducts are adequately sealed, insulated, and free from obstructions is essential for maintaining optimal ESP.

By considering these factors and implementing appropriate design and installation practices, HVAC professionals can effectively manage external static pressure. This, in turn, leads to improved system performance, energy efficiency, and overall comfort.

Measuring Duct External Static Pressure

When it comes to HVAC systems, measuring duct external static pressure is a crucial step in ensuring optimal performance. By accurately measuring the pressure differentials, technicians can identify any issues or inefficiencies in the system and make the necessary adjustments for improved airflow.

Tools Required for Measurement

To carry out this measurement, specific tools are required. The primary tool is a manometer, which can be either digital or analog. This device is designed to measure pressure differentials accurately. However, it is essential to have the appropriate adapters and hoses to connect the manometer to the duct system properly.

Having the right tools is essential, as they play a significant role in obtaining accurate measurements. Without the proper equipment, the measurements may be skewed, leading to incorrect interpretations and potential misdiagnosis of any underlying issues.

Step-by-Step Measurement Process

Measuring duct external static pressure involves a systematic process that should be followed diligently. By adhering to the following steps, technicians can ensure accurate and reliable results:

Ensure HVAC System is Running: Before taking any measurements, it is crucial to ensure that the HVAC system is running and air is flowing through the ducts. Without proper airflow, the pressure readings will not accurately represent the system's performance.

Position the Manometer: Place the manometer at the appropriate measurement point. This is typically near the equipment or at critical sections of the ductwork where pressure differentials are most likely to occur. By strategically positioning the manometer, technicians can gather valuable data that reflects the overall system performance.

Take Multiple Readings: To ensure accuracy, it is essential to take multiple readings at different locations within the duct system. This helps identify any inconsistencies or variations in pressure throughout the system. By gathering data from various points, technicians can obtain a comprehensive understanding of the system's performance and pinpoint any potential issues.

Analyze Readings: Once the readings have been obtained, it is crucial to analyze them in conjunction with the system specifications. By comparing the pressure measurements to the expected values, technicians can interpret the data effectively. This analysis allows them to identify any deviations or abnormalities, which can then be addressed to optimize system performance.

By following this step-by-step measurement process, technicians can gather accurate data on the duct external static pressure. This information is invaluable in diagnosing any potential issues within the HVAC system and implementing the necessary adjustments to enhance its overall efficiency.

Interpreting Duct External Static Pressure Readings

Normal vs. Abnormal Readings

When interpreting duct external static pressure readings, it is essential to understand the acceptable range for the specific HVAC system. This range varies depending on factors such as the type of equipment, duct design, and system requirements. Deviations from the normal range can indicate underlying issues and the need for further investigation.

Implications of High and Low Pressure Readings

High pressure readings may indicate a variety of problems, including undersized ductwork, excessive friction, or a blocked filter. On the other hand, low pressure readings can signal improper equipment operation, leaky ducts, or an oversized system. Understanding the implications of these readings is crucial for troubleshooting and resolving issues effectively.

Troubleshooting Duct External Static Pressure Issues

Common Problems and Their Causes

Several common issues can arise with duct external static pressure. These include duct leaks, blockages, improper duct sizing, and restricted airflow due to dirty filters. Identifying the root causes of these problems is necessary for finding appropriate solutions.

Potential Solutions and Fixes

Addressing duct external static pressure issues requires a systematic approach. Solutions may include repairing duct leaks, cleaning or replacing filters, resizing ductwork, or adjusting fan speeds. Consulting with an HVAC professional can help identify the best course of action for specific situations.

Conclusion

Understanding duct external static pressure is vital for maintaining optimal HVAC system performance. By grasping the basics, considering factors influencing ESP, employing proper measurement techniques, and troubleshooting issues effectively, homeowners and HVAC professionals can ensure efficient and balanced airflow throughout the ductwork system. Regular monitoring and timely interventions can help prevent potential problems and optimize heating and cooling comfort in homes and buildings.